Disposable — Coveralls

• Protective coverall CE Type 5 & 6

• 50gsm

• For fine dust particles

• Reduced spray and limited splash

• 2 way zip front with adhesive storm flap

• Elasticated cuffs, ankles, waist and hood

• Breathable fabric

• Ideal for hazardous waste removal

• Individually packaged

• Very economical

• EN13034 :2005 + A1:2009

• EN13982-1:2004 + A1:2010

• EN1149-5: 2008

• EN1073-2: 2002

• Protective coverall CE Type 5 & 6

• For fine dust particles

• Reduced spray and limited splash

• 2 way zip front with adhesive storm flap

• Elasticated cuffs, ankles, waist and hood

• Breathable fabric

• Ideal for hazardous waste removal

• Individually packaged

• Very economical

• EN13034 :2005 + A1:2009

• EN13982-1:2004 + A1:2010

• EN1149-5: 2008

• EN1073-2: 2002

• Protective coverall CE Type 5 & 6

• For fine dust particles, reduced spray and limited splash

• Anti static

• 2 way zip front with storm flap

• Elasticated cuffs, ankles, waist and hood

• Microporous breathable fabric

• Individually packaged

• Very economical

• EN 13034 :2005 + A1:2009

• EN 13982-1 :2004 + A1:2010

• EN 1149-5 :2008

• EN 14126 :2003 + AC :2004

• EN 1073-2: 2002

• Disposable coverall

• 60G microporous fabric

• Laminated finish

• Light spray and limited splash protection

• 2 way zip front with flap

• Elasticated cuffs, ankles, waist and hood

• Fully taped seams

• Individually packaged

• CE Type 4,5 & 6

Conforms to:

• EN 14605 :2005 + A1:2009

• EN 13034 :2005 + A1:2009

• EN 13982-1 :2004 + A1:2010

• EN 1149-5 :2008

• EN 14126 :2003 +AC:2004

• EN 1073-2 :2002

Microporous type 3/4/5/6 disposable coverall

• 90gm 56% SMS polypropylene, 44% polyethylene

• Polyethylene laminated +3 layers of polypropylene

• Ultrasonic taped seams

• Elasticated hood, wrists, ankles and waist

• Zip front with storm flap

• Elasticated thumb loops

Ideal uses:

• Maintenance & Repair

• Powder coating

• Insulation laying

• Pharmaceutical manufacture

• Paint spraying

• Wood & Metal processing

• Low level chemical handling

• Resin application

• Pressure/Steam water cleaning

• Fibreglass manufacture

Conforms to:

• EN 13688 :2013

• EN 14605 :2005 + A1 :2009

• EN ISO 13982-1 :2004 + A1 :2010

• EN 13034 :2005 + A1 :2009

• EN 14126 :2003

• EN 1073-2 :2003

• EN 1149-5 :2008

Protects against:

• Chemical & Viral agents (including Coronavirus)

• Bloodborne pathogens

• Sulphuric acid

• Contaminated liquids

• Radioactive Contamination

• For fine dust particles, reduced spray and limited splash

• Anti-static

• 2 way zip front with storm flap

• Elasticated cuffs, ankles, waist and hood

• Microporous fabric 54% polypropylene + 46% polyethylene

• Individually packaged

EN 13034: 2005 + A1: 2009

EN13982-1: 2005 + A1: 2010

EN 1149-5: 2018 Anti-Static – Material Performance and Design Requirements

EN 1073-2: 2002 Protective Clothing against radioactive contamination (no rays)

EN 14126: 2003 + AC:2004 Protective clothing against Infective agents (Type 5B, 6B)

• Fabric disposable boilersuit

• Non woven fabric

• 33gsm SMS (spunbond + meltblown + spunbond nonwovens)

• Elasticated hood

• Elasticated waistband and ankles

• No.3 nylon spiral one-way zip front opening

• Zip colour matches garment shell fabric.

• Fabric disposable boilersuit

• Non woven fabric

• 33gsm SMS (spunbond + meltblown + spunbond nonwovens)

• Elasticated hood

• Elasticated waistband and ankles

• No.3 nylon spiral one-way zip front opening

• Zip colour matches garment shell fabric.

• Non woven polypropylene

• Disposable visitors coat with collar

• Hook and loop fastening

The 4520 is made from extremely lightweight and breathable material and is designed to offer protection against hazardous dusts and limited liquid splashes.

• Elasticated hood, ankles and waist.

• 2 way zip with sealable tab on storm flap.

• 3- panel hood.

• Knitted cuffs.

• Low linting.

The 3M 4530 is designed to be lightweight and breathable whilst offering protection against hazardous dusts and limited liquid splashes. The material complies with ISO 14116:2008 for limited flame spread index 1 (must be worn over an index 2 or 3 garment).

Type 5/6

Elasticated hood, ankles and waist

2 way zip with fully sealable storm flap 3-panel hood Knitted cuffs Low linting

•Comfortable protection from hazardous particulates in general industrial environments

•Breathable, SMS material, Type 5/6 protection

•Protection - Proven to filter 100% of particles >3 microns(Kaken particle penetration test)

•Comfort - Air and water vapour permeable(breathable) to help reduce the risk of heat stress

•Silicone Free - critical in spray painting applications

•Optimised body fit - improves wearer comfort and safety

•elasticated hood, wrists, waist and ankles

ה-way front zipper with re-sealable storm flap

•EN ISO 13982-1:2004+A1:2010

•EN 13034:2005+A1:2009

•EN 1073-2:2002

• Highly breathable, antistatic suit used stripping, clear up or handling of asbestos, general maintenance, construction and contract cleaning

• 3-piece hood

• Elasticated hood, wrists, waist and ankles

• 2-way front zipper with re-sealable storm flap

• Finger loops

• Anti-static treatment

• Conforms to Type 5, 6, EN1073-2 and EN1149-5

• Provides both protection and comfort with exceptional liquid and particle protection

• 3-piece hood

• Elasticated hood, wrists, waist and ankles

• 2-way front zipper with resealable storm flap

• Finger loops

• Conforms to Type 5, 6, EN14126, EN1073-2 and EN1149-5

• White, Hooded coverall

• Type 5/6

• Stitched internal seams

• Elasticated wrists, ankles, and face

• Elasticated waist (glued-in)

• Zipper flap

CAT III

EN ISO 13982-1:2004 + A1:2010

EN 13034:2005 + A1:2009

EN 1073-2:2002

EN 1149-5:2018 (on inside)

• White, hooded coverall 3 piece hood.

• Elasticated face, wrist and ankles.

• Protection against particles and liquid splash.

• Must be worn over the top of a primary FR garment.

• Stitched external orange seams.

• Suitable for petrochemical, railway, welding and many other applications.

• Conforms to: CAT III, Type 5,6. EN 1073-2, EN 1149-5, EN 14116 Index 1

EN13688 - general performance requirements for ergonomics.

EN13982 - Type 5 test

EN13034 -Type 6 test

EN14325 - CE marking - protective clothing

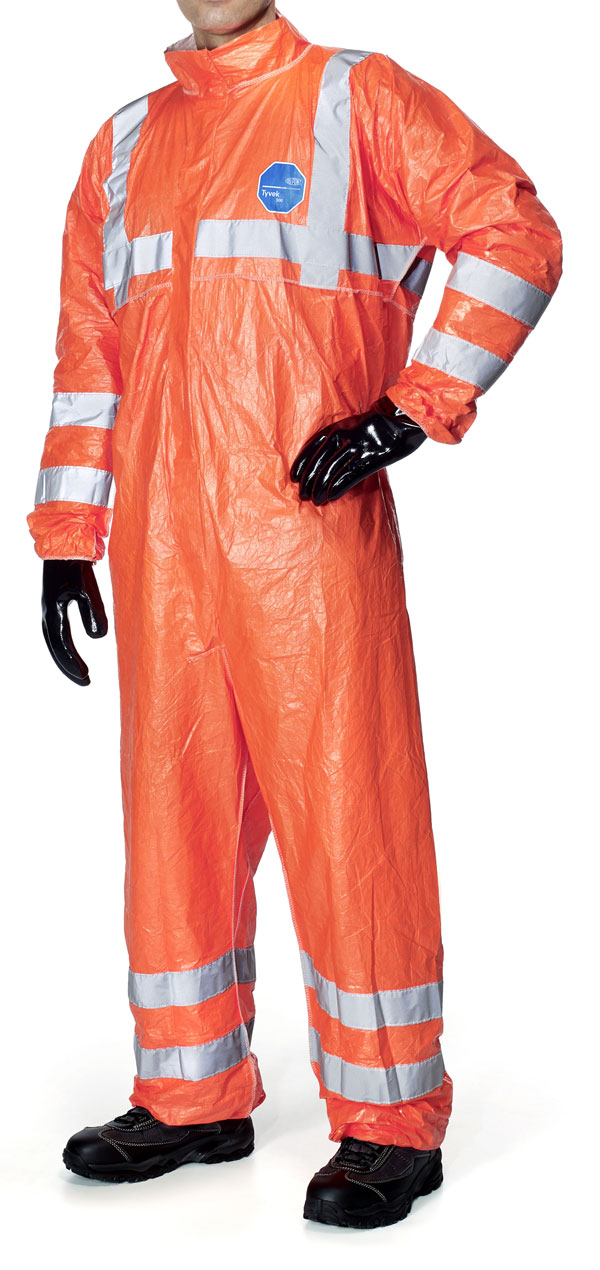

• Tyvek® 500 HV

• Flourescent Orange, collared coverall

• Robust, yet lightweight

• HV reflective bands

• Elasticated waist, wrists and ankles

• Excellent barrier to fine particles and fibres

• High Visibility that doesn't wash out

• Suitable for working in rail, mining,road, underground, waste, ports , airports and many other applications.

• Conforms to: CAT III, Type 5B, 6B. EN1073-2, EN1149-5 (inside), EN14126, EN ISO 20471 class 3/3

• Pictograms: CAT III, Type 5B, 6B. EN1073-2, EN1149-5 (inside), EN14126, EN ISO 20471 class 3/3

• RIS-3279-TOM Issue 1

• White, hooded coverall

• Attached socks and boot flaps

• Stitched and over taped seams

• Thumb loops

• Tunnelled elastication at wrists, ankles, and face

• Elasticated waist (glued-in)

• Tyvek zipper

• Self-adhesive zipper and chin flap

CAT III Type 4-B, 5-B, 6-B

EN 1073-2:2002

EN 14605:2005 + A1:2009

EN ISO 13982-1:2004 + A1:2010

EN 13034:2005 + A1:2009

EN 14126:2003

EN 1149-5:2008

Tyvek ® 800J

• White, hooded coverall

• Robust, yet lightweight

• Adhesive Chin Flap

• Elasticated face, wrist and ankles

• Thumb Loops

• Self-Adhesive Zipper Flap

• Stitched and over taped seams

• Effective Barrier for low concentrated water based inorganic chemicals and hazardous particulates

• Oil repellancy

• Suitable for industrial cleaning, petrochemical, sewers and maintenance and many other applications.

• Conforms to: CAT III, Type 3B, 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• Pictograms: CAT III, Type 3B, 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• Hooded coverall.

• Robust, yet lightweight.

• 3 piece hood.

• Elasticated face, wrist and ankles.

• Excellent barrier to fine particles and fibres.

• Ultra-low linting.

• Stitched external seams.

• Suitable for pharmaceutical, chemical processing, oil and gas industry, maintenance spray painting and many other applications.

• Conforms to: CAT III, TYPE 5B, 6B. EN 1073-2, EN 1149-5, EN14126

Tyvek ® Classic Plus

• White, hooded coverall

• Robust, yet lightweight

• Adhesive Chin Flap

• Elasticated face, wrist and ankles

• Thumb Loops

• Excellent barrier to fine particles and fibres

• Stitched and over taped seams

• Ultra-Low Linting

• Suitable for Pharmaceutical manufacturing, nuclear, laboratory, biohazards and many other applications.

• Conforms to: CAT III, Type 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• Pictograms: CAT III, Type 4B, 5B, 6B. EN 1073-2, EN 1149-5, EN14126

• EN 14605:2005 + A1:2009

• EN ISO 13982-1:2004 +A1:2010

• EN 13034:2005 + A1:2009

Tyvek® 500 Xpert

• White, Hooded coverall

• Ergonomic-protective design

• Stitched external seams

• Elasticated wrists, ankles and face

• Elasticated waist (glued-in)

• Tyvek® zipper and flap

• Conforms to: CAT III, TYPE 5B, 6B. EN 1073-2, EN14126, EN 1149-5 (on both sides)

• Hooded coverall

• Lightweight and durable (<700g)

• Adhesive chin flap

• Elasticated face, wrist and ankles

• Thumb loops

• Double cuffs, zippers and zip flaps

• Stitched and over seams

• Good barrier against organic and inorganic chemicals

• Suitable for oil and gas industry, chemical engineering, response teams and many other applications

• Conforms to: CAT III, Type 3B, 4B, 5B, 6B, EN 1073-2, EN 1149-5, EN14126

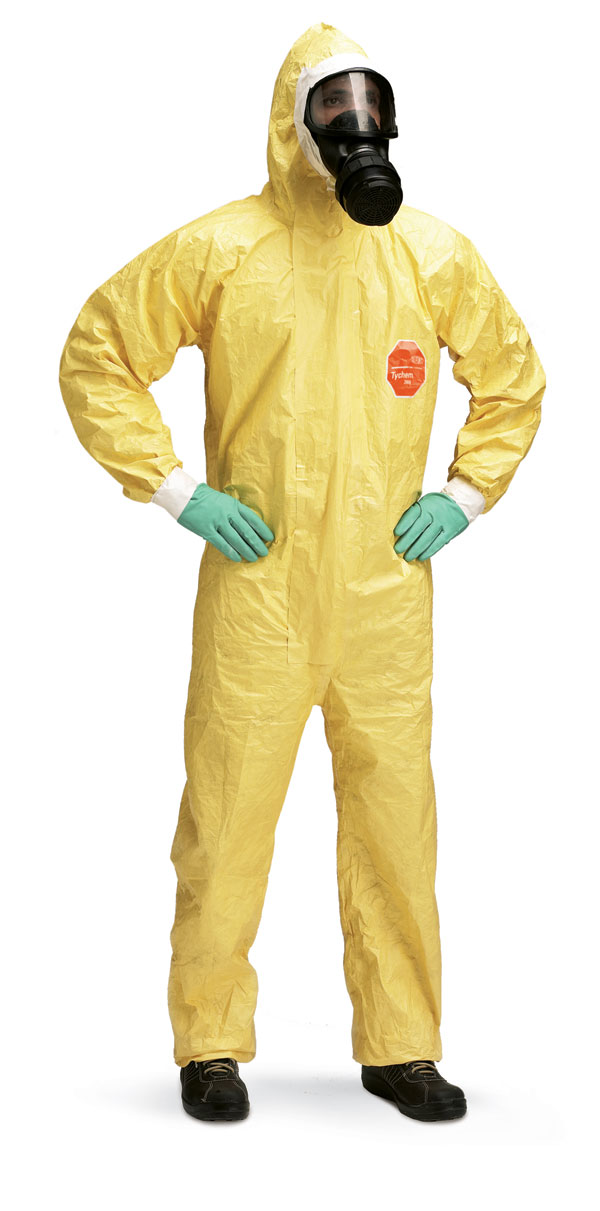

DuPont Tychem® C, model CHA5. Hooded coverall.

Available in bright yellow for high visibility.

• Elasticated face, wrists, waist and ankles for an optimal fit, thumb loops prevent sleeves from riding up.

• Self-adhesive chin flap for tight seal of suit to face-masks.

• Made from a lightweight and durable fabric (<450g per garment).

Tychem® C garments utilise the strength of Tyvek® and a polymeric barrier coating to offer good permeation barrier protection against a wide range of inorganic chemicals and biological hazards (even under pressure).

Tychem® C is used for splash or pressurised splash protection in a variety of industrial environments, including pulp and paper manufacturing, food processing, chemical processing and pharmaceutical manufacturing.

Chemical protective clothing, Category III, Type 3-B, 4-B, 5-B and 6-B

EN 14126 (barrier to infective agents), EN 1073-2 (protection against radioactive contamination)

Antistatic treatment (EN 1149-5) - on inside

Stitched and over-taped seams with barrier tape for protection and strength.

Self-adhesive double zipper flap closure system for higher protection.